Tesla Robots Get X-Men Names

Originally published on Planetsave.

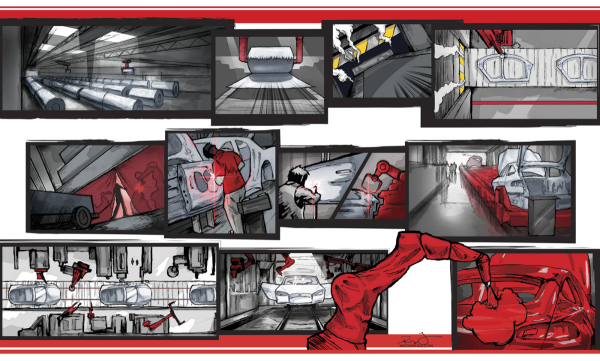

Tesla Motors announced late last night (well, late last night over here in Europe) that it was implementing some factory upgrades. Going from a production of 0 not very many years ago to 22,000 last year, and then to 35,000 this year, has been quite a ride… but it’s just the beginning. With factory upgrades, Tesla is aiming to increase production another 50% by the end of 2015, including the beginning of Tesla Model X production.

Always eager to have a bit of fun with its names and give tribute to its geeky roots, during this latest factory upgrade, Tesla decided to name some of its new robots after X-Men characters. I’m sure this is something that Elon Musk’s buddy Jon Favreau (director of the latest Iron Man series and Avengers) had a little laugh at. Who knows — maybe it was actually his idea.

Here’s what the different “X-Men characters” do, according to Tesla:

- Xavier: “stands at the entrance to the trim line, lifting cars down to the floor from an electrified rail.

- Iceman, Wolverine, and Beast: engage in heavy lifting.

- Storm and Colossus: “can be found at the end of the chassis line.”

- Vulcan and Havok: “work as a team to lift cars back onto the rail.”

10 of the world’s largest robots are now installed and working hard in Tesla’s Fremont factory.

Tesla notes that, “To us, these robots are like superheroes, so we figured they deserved superhero names.” That’s fun and all, but I think it’s a bit too easy to gloss over the significance of the matter. An electric vehicle revolution is critical to us stopping global warming and truly catastrophic climate change. It doesn’t do the job by itself, but it’s one important ingredient. Tesla is, inarguably, leading this revolution. Without Tesla, we’d have electric vehicles, but no revolution in the near future. Of course, its X-Men superheroes are an important part of its success.

Tesla Factory Upgrade from Tesla Motors on Vimeo.

Getting into more of the nuts and bolts of recent factory upgrades, Tesla writes:

The most dramatic changes are to be found in general assembly, where we’ve eliminated a lot of overhead steel and mechanical structures in favor of advanced robots that can lift and maneuver entire cars with optimum precision while taking up less room. Soon, our new robots will even be able to install battery packs in the cars, relieving humans of the most labor-intensive operation in the factory and reducing installation time from four to two minutes.

… Alongside the robots, we’ve created a more efficient floor plan with significantly more automation. In addition, the cars now move down the assembly line as associates work on them, enabling a streamlined and more consistent workflow. The line is now running at about 1,000 cars a week with the potential for significantly more with minor adjustments.

High Efficiency Electric Drive Unit from Tesla Motors on Vimeo.

To read more about the improvements made to the Tesla Motors factory in Fremont, California, including ways that it is making its workplace nicer for the human employees, check out the full Tesla Motors blog post.

Sign up for CleanTechnica's Weekly Substack for Zach and Scott's in-depth analyses and high level summaries, sign up for our daily newsletter, and follow us on Google News!

Whether you have solar power or not, please complete our latest solar power survey.

Whether you have solar power or not, please complete our latest solar power survey.

Have a tip for CleanTechnica? Want to advertise? Want to suggest a guest for our CleanTech Talk podcast? Contact us here.

Sign up for our daily newsletter for 15 new cleantech stories a day. Or sign up for our weekly one on top stories of the week if daily is too frequent.

CleanTechnica uses affiliate links. See our policy here.

CleanTechnica's Comment Policy